Poka-Yoke Explained: How Simple Design Eliminates Factory Mistakes Forever

Manufacturing systems operate in an environment where precision, repeatability, and predictability directly influence cost, quality, and safety.

Yet, no matter how well-trained or experienced the workforce is, human error remains an unavoidable component of industrial activity.

Even the most disciplined operators can momentarily lose focus, misinterpret instructions, or mishandle components.

In high-volume or high-precision production, a single slip can propagate into a batch-level defect, costly rework, or even product recalls.

This is where Poka-Yoke, the Japanese concept of mistake-proofing, becomes indispensable.

Introduced as part of the Toyota Production System (TPS), Poka-Yoke represents not just a collection of devices but an engineering philosophy: designing processes so mistakes cannot occur or cannot escape detection.

In today’s landscape of digital transformation, advanced sensors, machine vision, and data-driven automation have expanded the boundaries of traditional Poka-Yoke thinking.

Yet the core idea remains the same: prevent errors, reduce variability, and safeguard quality at the source.

This article offers a comprehensive, industry oriented exploration of Poka-Yoke principles, applications, implementations, and best practices across major manufacturing sectors.

What is Poka-Yoke?

The term “poka-yoke” originates from the Japanese words “poka” (mistake) and “yokeru” (to avoid).

Poka-yoke is a methodology designed to prevent errors, detect them instantly, and minimize their impact.

It aims to build quality into the process rather than inspecting it afterward.

Poka-Yoke supports zero-defect manufacturing and ensures that downstream processes receive components in the correct state consistently.

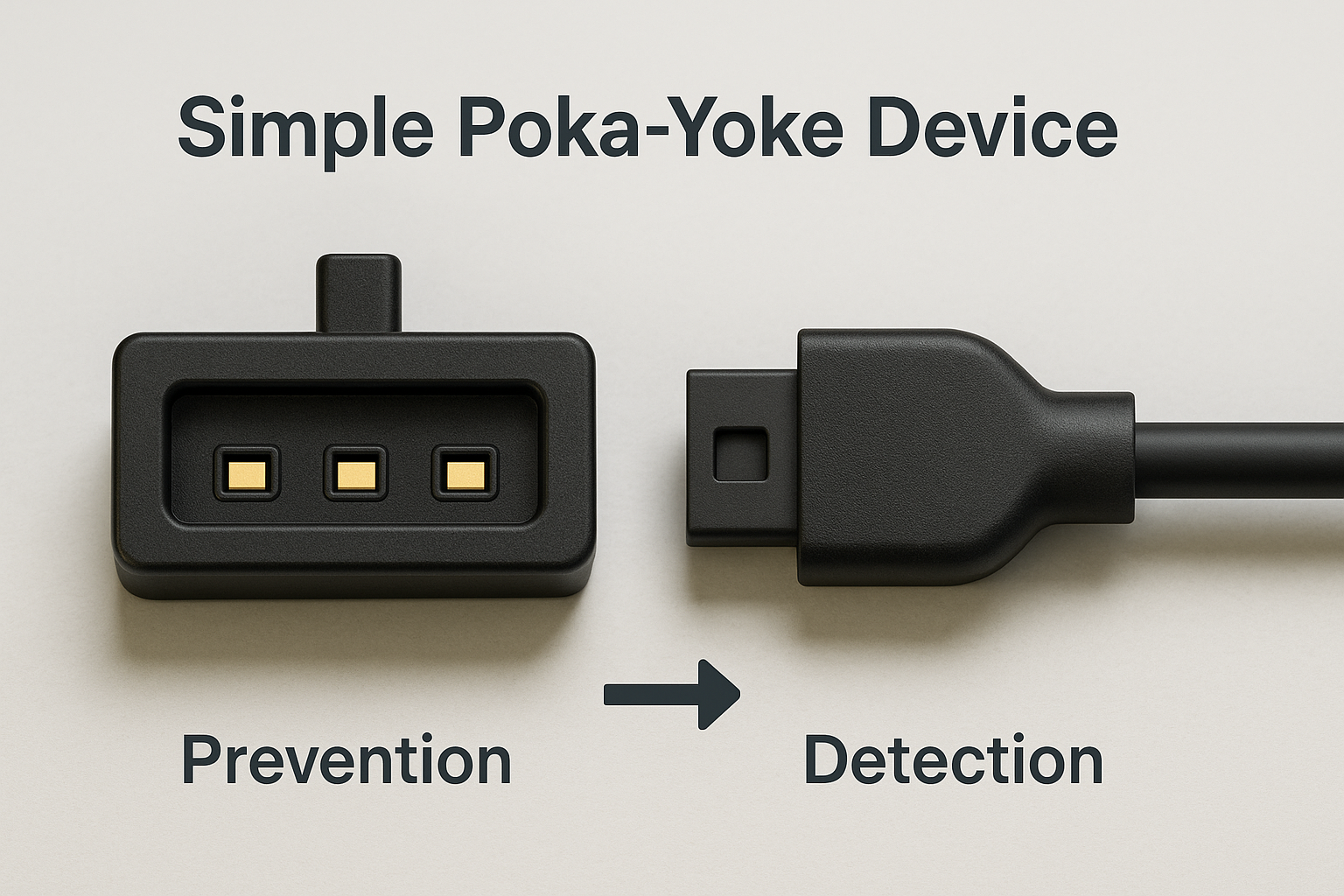

Unlike traditional inspection, which identifies errors after occurrence, Poka-Yoke prevents errors from occurring in the first place or stops them immediately at their source.

How Poka-Yoke Works

The logic behind Poka-Yoke is simple: make the correct action the easiest action, and make the incorrect action physically or logically impossible.

Poka-Yoke may:

• Eliminate ambiguity

• Control orientation

• Restrict incorrect sequences

• Detect omissions

• Provide real-time feedback

• Halt production when conditions are unsafe.

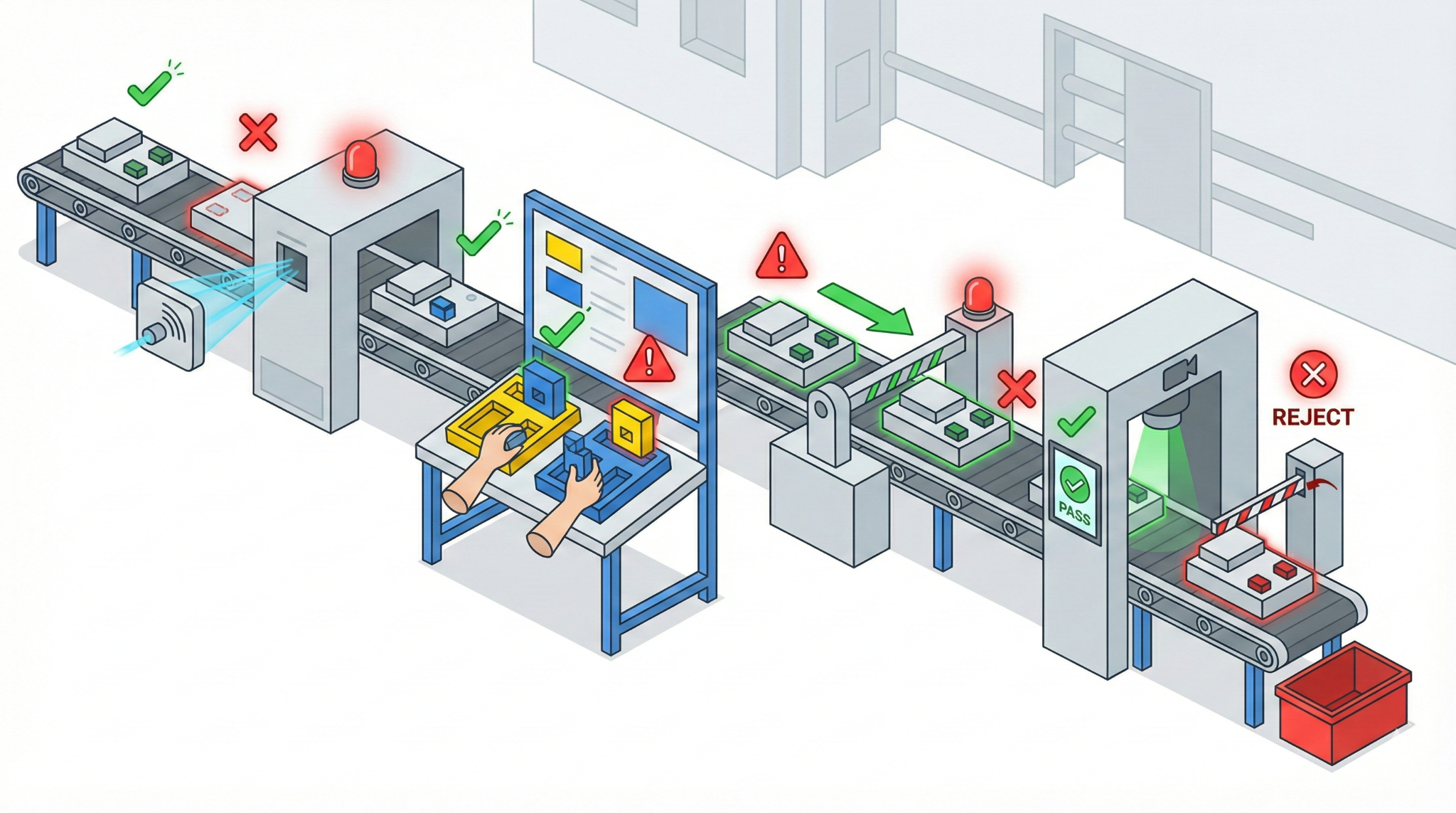

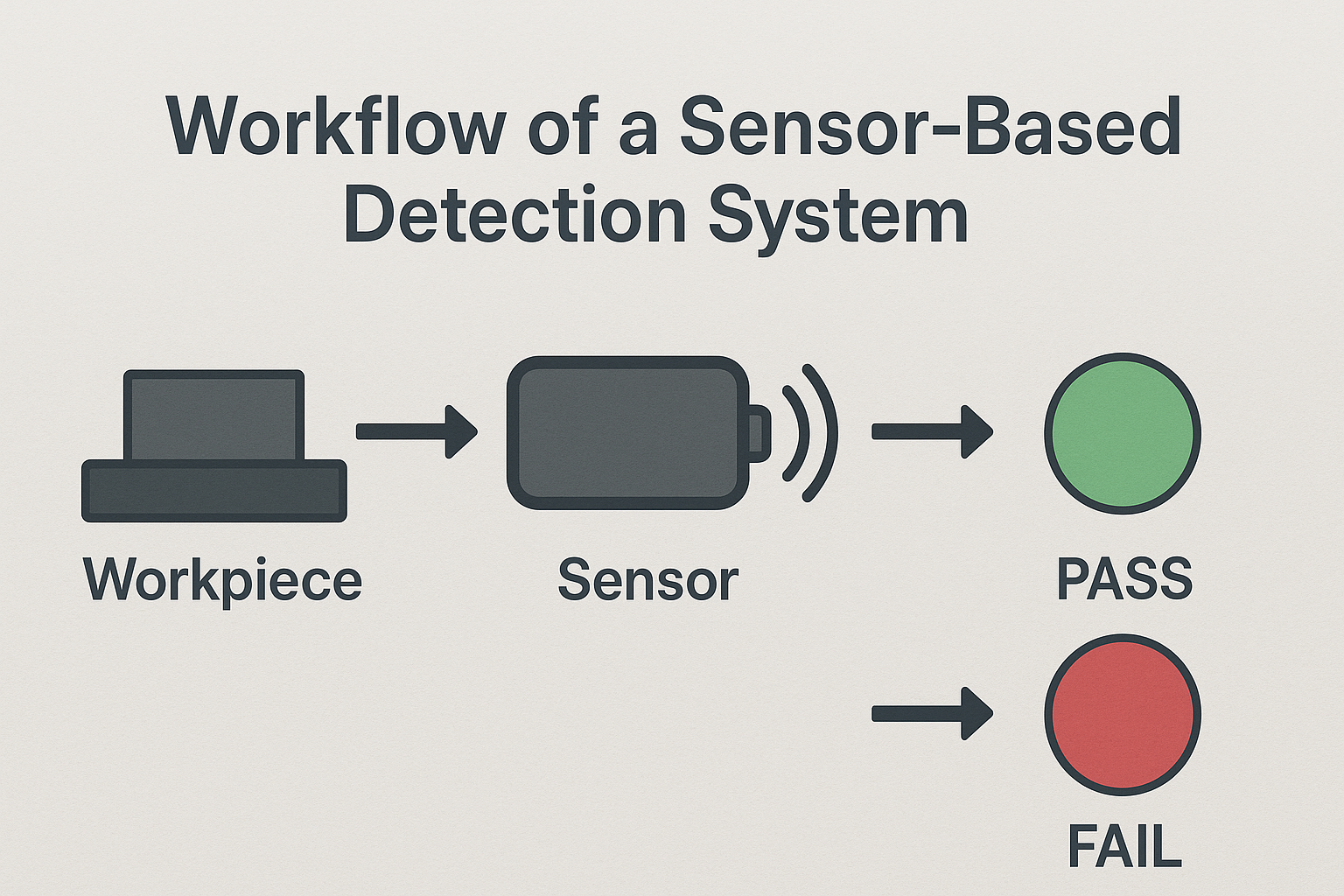

Common devices include fixtures, jigs, sensors, interlocks, and automated feedback systems. Although advanced technology is available, many of the most effective Poka-Yoke techniques remain simple, robust, and low-cost.

Types of Poka-Yoke Methods

Poka-Yoke systems are typically classified into

1. Control Methods:

Mechanisms that actively prevent the process from continuing unless the correct conditions are met. Examples include interlocks, force-fitted jigs, and presence-detection sensors.

2. Warning Methods:

Systems that alert operators about potential errors without stopping production automatically. These include alarms, lights, pop-up messages, and mismatch indicators.

Control methods are generally more reliable, while warning methods are useful in supporting human decision-making.

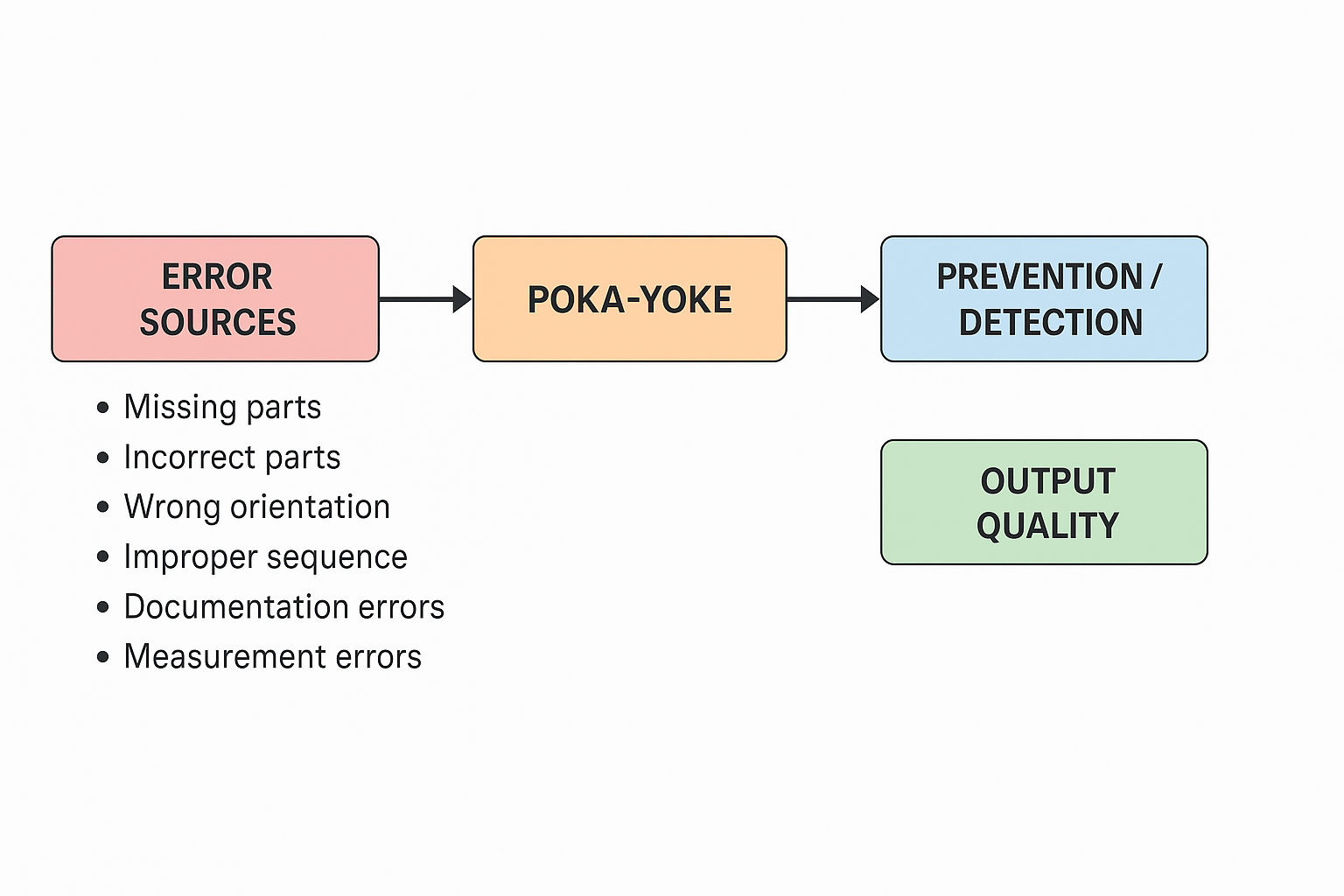

Categories of Errors Prevented

Poka-Yoke techniques address predictable categories of industrial errors:

• Missing parts

• Incorrect parts

• Wrong orientation

• Incorrect assembly sequence

• Dimensional errors

• Documentation or labeling errors

By anticipating common human mistakes, Poka-Yoke improves consistency and strengthens process reliability across the production line.

Real-World Examples in Manufacturing

Automotive Manufacturing:

The automotive sector heavily relies on mistake-proofing due to safety-critical components.

Examples include orientation-specific fixtures, keyed connectors, torque sensors, and machine vision systems verifying part presence.

Electronics Manufacturing:

Given extremely tight tolerances, electronics production uses Automated Optical Inspection (AOI), polarized components with keyed insertion, and bowl feeders ensuring correct orientation.

Food & FMCG:

Packaging, filling, and sealing processes use fill-level sensors, cap alignment detection, and material presence verification to maintain consistency and safety.

Medical Devices:

Barcode verification, interlocked sterilization systems, and shape-specific tools ensure high reliability and compliance.

Everyday Examples:

Microwaves that operate only when closed, cars requiring the brake or clutch before starting, and USB-C ports that eliminate orientation errors provide familiar analogies.

Benefits of Implementing Poka-Yoke

Poka-Yoke provides wide-ranging benefits:

• Defect prevention and reduction of scrap – which improves raw material use

• Increased process efficiency

• Lower operator dependency – which reduces human stress

• Improved safety

• Cost savings through reduced rework – greatly reducing cost of production itself

• Compliance with industry standards (ISO, GMP) – allowing greater acceptance of the product

How to Implement Poka-Yoke

Effective implementation involves:

1. Identifying failure modes through FMEA (Fault Mode Effects Analysis), defect logs, and operator feedback

2. Understanding the process physically and mechanically

3. Choosing between control or warning methods

4. Prototyping solutions using low-cost mockups

5. Integrating sensors and automation where necessary

6. Testing solutions under real production conditions

7. Documenting and training operators of machines and equipments

8. Reviewing and updating Poka-Yoke related documents regularly as processes evolve

Challenges and Limitations

Despite its strengths, Poka-Yoke faces challenges:

• Over-engineering leading to high maintenance

• False alarms reducing operator trust

• Part variation disrupting detection systems

• Resistance from operators or management

• Physical limits in preventing certain cognitive or judgment-based errors

Simplicity and consistency remain key to long-term success.

Poka-Yoke and the Future of Smart Manufacturing

Industry 4.0 technologies are transforming traditional error-proofing:

• Machine vision systems detect orientation, micro-defects, and cosmetic issues

• IoT sensors enhance detection of vibration, temperature, or load anomalies

• AI-driven predictive quality forecasts potential failures before they occur

• Robotics and AGVs (Automated Guided Vehicles) reduce human handling errors

• Digital twins allow virtual testing of Poka-Yoke designs

• RFID (Radio Frequency Identification) and barcode-based MES (Manufacturing Execution System) systems prevent material mix-ups

The future of Poka-Yoke lies in intelligent, predictive, and interconnected error-prevention systems.

Summary and Strategic Implications

Poka-Yoke stands as one of the most practical and transformative methodologies in modern manufacturing.

By designing processes that prevent or instantly detect mistakes, manufacturers achieve higher quality, improved safety, reduced costs, and more stable production flows.

As automation, AI, and digital systems expand, Poka-Yoke continues to evolve by combining physical constraints with intelligent sensing and predictive analytics to advance toward zero-defect manufacturing.